Portland cement is a fine powder produced by grinding Portland cement clinker (more than 90%), a limited amount of gypsum (calcium sulphate dehydrate – CaSO4.2H2O, which controls the set time) and other minor constituents which can be used to vary the properties of the final cement.

Portland cement clinker is a hydraulic material which shall consist of at least two-thirds by mass of calcium silicates (3CaO.SiO2 and 2CaO.SiO2), the remainder consisting of aluminum and iron containing clinker phases and other compounds. The ratio of CaO to SiO2 shall not be less than 2.0. The magnesium oxide content (MgO) shall not exceed 5.0% by mass.

Iran Cement Clinker is well-known among Cement Manufacturers, Trading Companies, and Business persons in the Cement industry worldwide because of its outstanding quality. A total of 6.7 million tons of Iran Cement and 10.8 million tons of Clinker were exported in the last Iranian year (March 2019-20), chiefly to Iraq, Kuwait, China, Bangladesh, India, littoral states of the Persian Gulf, and Central Asian countries.

When comparing the sustainability, performance, cost efficiency, competence requirement, it can be concluding that Iran cement industries and suppliers are on the top levels on global rank. We are honestly pleased to present you best quality Portland Cement with highest services to meet your requirement.

Portland Cement (type I & II)

Typical Specifications

Type I (Moderate Sulfate Resistance) ASTM C150

Type II (Moderate Sulfate Resistance) ISIRI 389

Portland Cement (type IV & V)

Typical Specifications

Type IV (Sulfate Resistance) ASTM C150

Type V (Sulfate Resistance) ISIRI 389

Mahallat County in Markazi Province of Iran is the hub of decorative stone production. There are 70 active stone mines in Mahallat that possesses 30 million tons of mineral reserves, 2 million tons of which are extracted annually. Over 2% of the world’s construction and travertine stones are produced in Mahallat. Some 280 processing units, with a capacity of 18 million square meters of stone, are active there.

According to Malek Rahmati, vice chairman of Iran Stone Association, Iran ranks third in terms of variety and production of ornamental stones after China and India. Iranian stone processing units have a nominal production capacity of 180 million square meters per year.

This kind of tiles are resistant in high temperatures. We have unique models with different patterns in our collection. It is cost effective and never ever lost shine! Granit tile designs are vein, Soluabel Salt and sparek. We have different colors of granite tile usually with thickness of 2 cm.

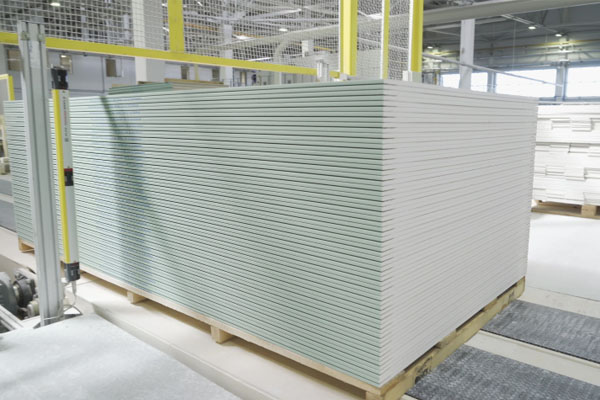

Due to its inherent fire resistance, gypsum board, commonly known as drywall is the premier building material for wall, ceiling, and partition systems in residential, institutional, and commercial structures. Designed to provide a monolithic surface when joints and fastener heads are covered with a joint treatment system, gypsum products also provide sound control, economy, versatility, quality, and convenience.

Gypsum board is the technical product name used by manufacturers for a specific board with a gypsum core and a paper facing.

Gypsum board is one of many gypsum panel products, defined in ASTM C11, Standard Terminology Relating to Gypsum and Related Building Materials and Systems, as “the general name for a family of sheet products consisting essentially of gypsum.” This term includes gypsum board, glass mat gypsum panels, abuse-resistant, and impact-resistant gypsum panels and gypsum shaft liner panels.